Eductor calculations

Eductor calculations

Steam Ejector Design

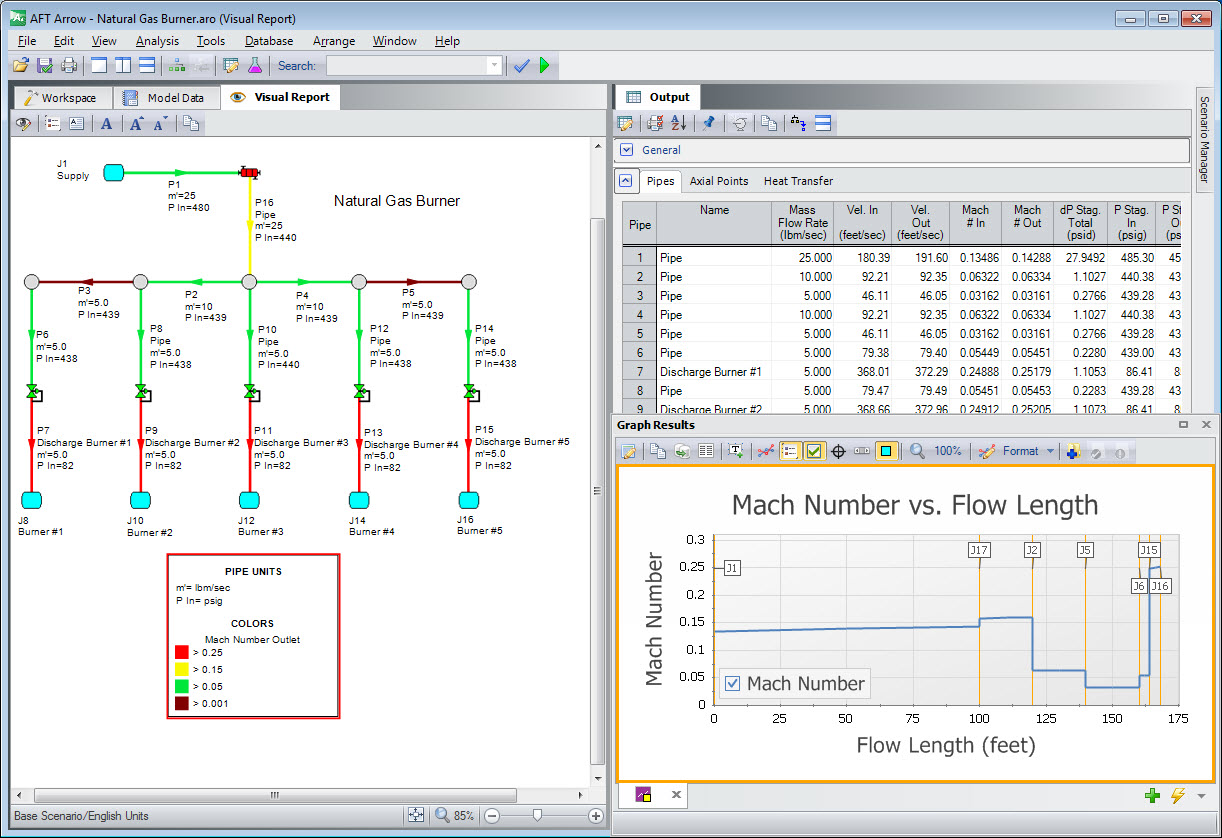

Mar 23, 2012 - ejectors, which were specifically designed for the process rather than. The calculation of Pr3 will then enable the dimensions of the mixing. A Transvac Ejector (venturi, eductor, jet pump) operation is based upon Bernoulli’s Principle which states: ‘When the speed of a fluid increases its pressure decreases and vice versa’. Calculations for. They are especially effective in the chemical industry where an on-site supply of steam ejector calculation Free Download, steam ejector design software, steam. Do you need an ejector design done for you? Ezejector can size and specify ejectors for a wide range of applications.

Anyone have experience with eductors?

I am a new engineer and am looking for pointers on calculating the flowrate needed to move a gas.

We have up to a 150# steam supply as the motive stream. The question is what pressure can we regulate this steam to in order to still maintain the flow.

We are passing the steam at some pressure (this is what is to be determined) through the eductor to induce the flow of a stack gas, which is at or near atmospheric pressure (may actually be a slight vacuum). The outlet of the eductor will have a stack gas/steam mixture that will then be returned to the stack. This flow will serve as a 'fast loop' that every so often an analyzer will pull a 'slip stream' from to test.

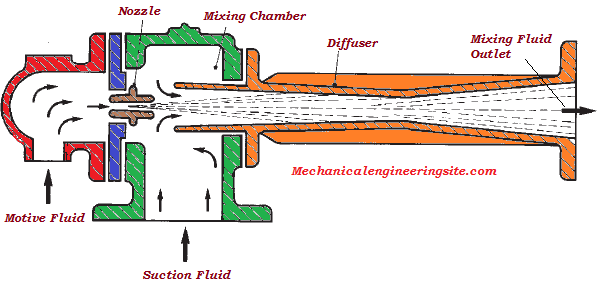

Any suggestions as to how to formulate a relation of motive stream to outlet pressure? The eductor used for gases is basically a converging/diverging nozzle from what I understand. The pressure of the motive stream is dropped, to increase its velocity. This in turn sucks the stack gas into the eductor. The two then exit the eductor at an intermediate pressure.

Also, any good sites that thoroughly explain steam usage in refineries? I am looking for something that starts with the basics of steam.

Thank you...

I am a new engineer and am looking for pointers on calculating the flowrate needed to move a gas.

We have up to a 150# steam supply as the motive stream. The question is what pressure can we regulate this steam to in order to still maintain the flow.

We are passing the steam at some pressure (this is what is to be determined) through the eductor to induce the flow of a stack gas, which is at or near atmospheric pressure (may actually be a slight vacuum). The outlet of the eductor will have a stack gas/steam mixture that will then be returned to the stack. This flow will serve as a 'fast loop' that every so often an analyzer will pull a 'slip stream' from to test.

Any suggestions as to how to formulate a relation of motive stream to outlet pressure? The eductor used for gases is basically a converging/diverging nozzle from what I understand. The pressure of the motive stream is dropped, to increase its velocity. This in turn sucks the stack gas into the eductor. The two then exit the eductor at an intermediate pressure.

Also, any good sites that thoroughly explain steam usage in refineries? I am looking for something that starts with the basics of steam.

Thank you...

Gas Ejector Design Calculation Xls

- The purpose is to study ejector devices on a basis as generalI(cont'd I JAN 73 1473 EDITION OF I NOV 65 IS OBSOLETE UNCLASSIFIEDI.

- A method of calculation for the ejector design using the correlations is also developed. R141b is shown in the present study to be a good working fluid for an ejector. The measured ω for the ejectors used in the present study can reach as high as 0.54 at Pg = 0.465 MPa (84 °C), Pc. = 0.087 MPa (28 °C) and Pe = 0.040 MPa (8 °C).

- Therefore ejector curves at fixed ejector geometry are calculated at the design discharge pressure and an increased discharge pressure (see 3.2). These are more indicative of the response of a specific ejector to changes in inputs.